Services

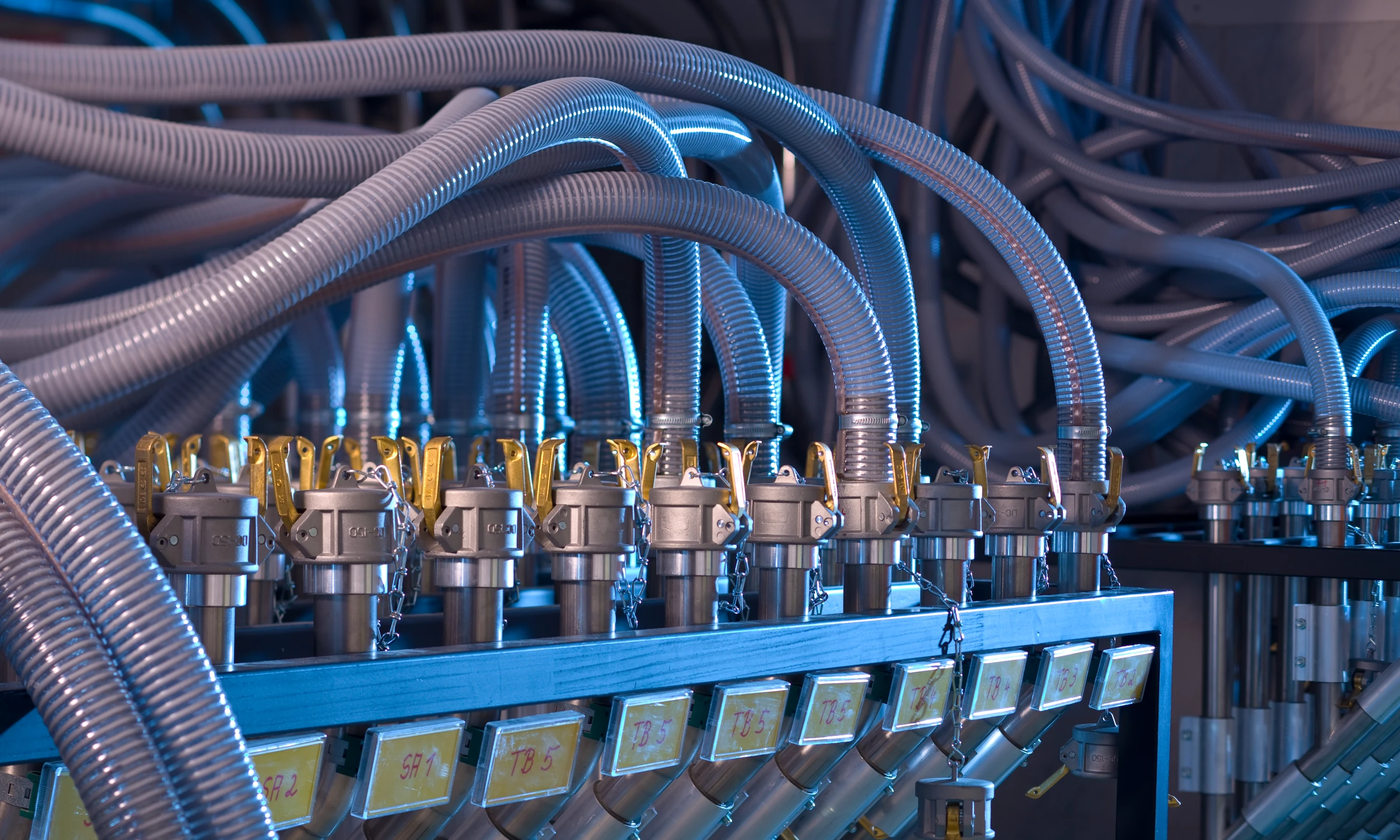

State-of-the-art equipment

We manufacture high-quality injection moulded items on the latest machines (25 to 320-tonne closing pressure) in a three-shift operation. We also guarantee consistent quality through continuous checks and documentation. Alongside the standard range we also develop tailored solutions in collaboration with customers.

Clean room

Our class 7 cleanroom ensures a dust-free environment for our caps and containers for the medical, pharmaceutical and cosmetics industry from production right through to automated counting and packaging. Our injection moulding machines are suitable for customised and standard caps.

Certificates

This certification is testament to our commitment to quality management and continuous improvement. It guarantees you products and services of the highest calibre. Our staff are trained to adhere to the established quality standards to meet your requirements.